AX 2012 Lean Manufacturing: Flushing principles and picking activities

You are here: >AX 2012 Lean Manufacturing: Flushing principles and picking activities

Abstract: How to utilize flushing principles and picking activities within Lean Manufacturing in AX2012 to reflect item consumption during production process.

One of the most important concept with AX2012 Lean Manufacturing is the setup of picking activities and flushing principles. The combination of the two can reflect different item consumption strategies to tailor to various production processes. The flexibility of picking activities allows allocation of material consumption to specific activities. The flushing principle then determines when the material is consumed in the production flow.

Picking activities are set up per process activity of a production flow within the Lean Manufacturing module in AX2012. Users can always add new picking activities with a specific item number, warehouse, and location. This allows items to be picked at the correct process, from the correct location for multiple activity Kanbans. To reduce setup, default picking activities can also be utilized. Default picking activities do not have the specifics. Instead they act as a blanket setup that catches all items. Now the question is, what if I have multiple activities in my production flow, and all of them have default picking activities? Where would the items be picked?

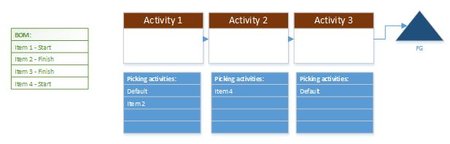

Standard Dynamics AX comes with 3 different flushing principles, start, manual, and finish. To answer the previous questions, if items are set to start, they would be consumed at the first activity with the default picking activity. This does not necessarily mean the start of the production flow, given that not every process activity needs to have a picking activity. If BOM items are set to flushing principle finish, then they will be consumed at the last activity with default picking activity. Keep in mind, each process activity can have both default and specific picking activities. With the combination of these two setups, we can quickly allocate our materials effectively while reducing setup in AX. Below is an example of a production flow, with a BOM complete with flushing principles.

Let’s take a look as we go down the BOM:

Item 1 has Start as the flushing principle. However, there’s no specific picking activity for Item1 so that it will be picked up at with the first default picking activity; therefore, at Activity 1.

Item 2 has Finish as the flushing principle, but since there’s a specific picking activity for Item 2, it is allocated to the picking list of activity 1 as well. Do note, Item 1 will be deducted from inventory upon start of Activity 1, while Item 2 will be deducted from inventory upon completion of Activity 1 due to their flushing principles.

Item 3 has Finish as the flushing principle. Since there’s no specific picking activity for it, the last default picking activity will add Item 3 to the picking list, therefore, Activity 3.

Item 4 has Start as the flushing principle. With the specific picking activity at Activity 2, Item 4 will be deducted from inventory upon start of Activity 2.

The example may seem a little too simplistic, but in a real production environment, there could be tens and hundreds of different parts. Given that flushing principles are taken into consideration during data migration, manipulation on picking activities can actually reflect when items should be selected, how production should be costed, and meanwhile reducing system setup within the Lean Manufacturing module in AX2012.

Written by: Patrick Chen

- About Us

- Partners

- Careers

- Contact us

- eBECS and the Microsoft Core Data Platform

- Microsoft Dynamics NAV in Property Management

- Microsoft Dynamics Nav Manufacturing Solutions

- Microsoft Dynamics NAV Cloud pricing

- Drive your Azure Momentum with SQL Managed Instance

- Compare Microsoft Dynamics AX VS NAV

- Microsoft Azure Data Centre Migration Guide

- Microsoft Dynamics 365 Business Central or 365 for Finance & Operations?

- Introduction to Microsoft Dynamics 365 for Finance and Operations

- Microsoft Dynamics 365 Business Central or 365 for Finance & Operations? Thank You

- Microsoft Dynamics 365 Business Central or Dynamics 365 Finance

- Compare Microsoft ERP Solutions

- Compare Microsoft ERP Solutions, Dynamics NAV vs Dynamics 365 Business Central

- Microsoft Dynamics 365 Business Central Price

- Compare Microsoft ERP

Categories

- AI (3)

- Azure (2)

- Business Insights (1)

- Canvas Apps (1)

- Common Data Service (2)

- Crisis Communication (1)

- CRM (3)

- Customer Data Platform (1)

- Customer Insights (1)

- Data Analytics/BI (29)

- Data Management (1)

- Data Warehouse (1)

- Dynamics 365 (33)

- Dynamics 365 Finance (1)

- Dynamics 365 Sales Insights (1)

- Dynamics 365 Supply Chain Management (1)

- Dynamics AX (50)

- Dynamics CRM (22)

- Dynamics Field Service (10)

- Dynamics NAV (10)

- Dynamics Project Service Automation (PSA) (15)

- eBECS (4)

- eBECS Marketing (1)

- eBECS Policies (1)

- ERP (2)

- Internet of Things (IoT) (15)

- Master Planning AX (4)

- Microsoft 365 (1)

- Microsoft Lifecycle Services (4)

- Power Apps (4)

- Power Automate (3)

- Power BI (1)

- Power Platform (6)

- Power VIrtual Agent (1)

- PowerApps (2)

- Project Service Automation (2)

- Quality Management (1)

- Sales (1)

- Surface Hub (3)

- Top Tips (1)

News

Upcoming Events - Register Now

Join our list

eBECS will invite you to webinars, events and keep you up to date with relevant news. You can unsubscribe at any time.