Production Floor Control and Management Made Easier in the new Microsoft Dynamics AX (V7)

You are here: >Production Floor Control and Management Made Easier in the new Microsoft Dynamics AX (V7)

With the new Workspace feature and improved forms in the new Microsoft Dynamics AX, Production management has never been easier. With just a few clicks of the mouse, a warehouse planner or production manager can get to the most valuable and important pieces of information. However, before we get into improvements in the new Microsoft Dynamics (AX7), let’s take a look at the manufacturing reasons for upgrade from the previous version Microsoft Dynamics AX2009 to Microsoft Dynamics AX2012. These features in Microsoft Dynamics AX2012 are now the bread and butter of the V7 functionality.

Microsoft Dynamics AX2012 R2 and R3 Manufacturing features not available in Microsoft Dynamics AX2009:

Changes to Process Manufacturing

- Sequence planned batch orders in order to reduce changeover times by sorting products into a sequence.

- Define formula ingredients for shelf life inheritance from finished goods.

- Define and activate formula ingredients for batch attribute inheritance.

- Define attribute-based pricing for a potency item.

- Inventory quantity is calculated automatically for catch weight items in process manufacturing.

Changes to Lean Manufacturing

- Upgrade from Lean manufacturing for Microsoft Dynamics AX 2009. New code means no upgrade task. Also Lean manufacturing became a standard module in Microsoft Dynamics AX2012, where it was a Microsoft owned add-on during the lifecycle of AX2009.

- Use production flows and activities to model a lean manufacturing basis. Production flows would be the sequence of activities, resource groups model work cells, and production flow models define the capacity of the work cells.

- Implement a Lean replenishment system by using Kanbans to signal demand requirements and setup Kanban rules to implement different replenishment strategies.

- Fixed Kanbans can be used to replenish target inventory levels.

- New Kanban boards to view, plan, and run Kanban jobs that are scheduled for a work cell.

- The Kanban framework allows printing of Kanban cards and picking lists to help register and track jobs in the warehouse and production floor.

General Changes to Production Control

- The Supply Schedule is a new form to see a summary of the current supply and demand and gives the user the ability to view product supply information (with planning, location, and time bucket filters), monitor and analyze the current state of supply, and make changes to planned supply.

- Period templates can be used to define schedules or time buckets.

- Shop floor control module is divided into two new feature sets: Time and Attendance and Manufacturing Execution. Think of Time and Attendance as the rules for time setups, registration, and payroll, while MES allows workers to create and transfer time registration for production, projects, and indirect activities, like meetings.

- Microsoft Dynamics AX2012 R3 introduced a new option for material reservations during the Release stage of a production order. This can be done manually for any order or set as a default in Production control parameters.

- WAX and TRAX was purchased by MS from Blue Horseshoe to introduce advanced Warehouse Management. This is important because it comes with an out-of-the-box feature to perform transactions on any Windows enabled Mobile device by connection to the Mobile Device portal. Productions orders can be started, pick materials, and RAF’d in the Mobile Device through Warehouse Management.

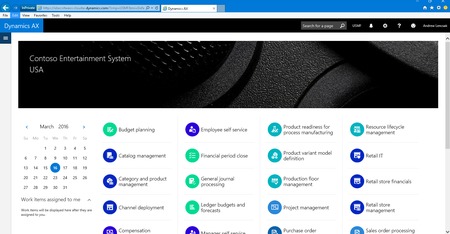

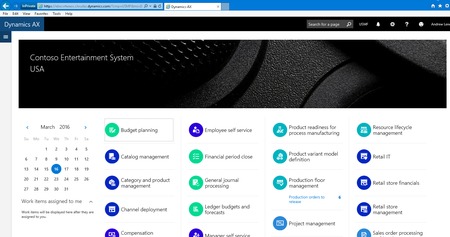

Now, let’s take a look at some basic configuration in AX7 to get even the beginner Microsoft Dynamics AX users up and running. First, use the workspace dashboard to navigate to the Production Floor Management workspace.

Then you can use the navigation pane on the left to make the Workspace a Favorite just by hovering over the menu item and selecting the Star icon. Favorites, as in previous Microsoft Dynamics AX versions, allows you to group links or menus that you use most frequently for easy access in the navigation pane.

This is a similar function that you would see when using most browser-based products, more user-friendly and familiar to today’s users than the right-click process used in earlier versions.

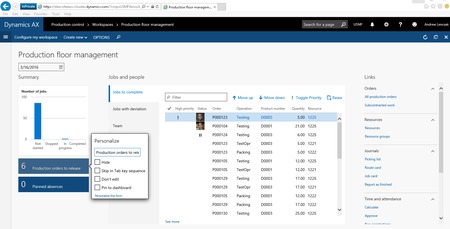

Personalization is also quite simple. For example, I now have Production Floor Management saved as a Favorite workspace, but say I want to further make the “Production orders to release” form more accessible. If I right click on the form and select “Personalize,” for example, I can rename it to something more suitable to my organization, or I can pin it to the dashboard:

If pinned to the dashboard, the form will display like below when you are at the main dashboard:

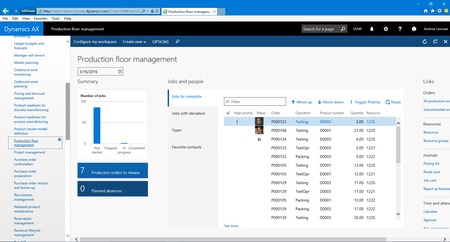

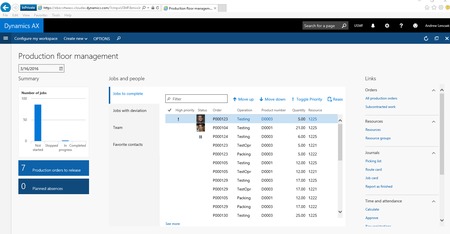

The workspace itself immediately gives the user a snapshot of some KPIs and important links rather than a full module. This makes it easier to get to the information you need quickly. The module access is still there, but you use workspaces on a daily basis to get your daily tasks done. Just look at the options available in the workspace page:

- The workspace is configurable straight from the interface to filter on Production Units or Resources if required. That enables each production line manager to have their own set of KPIs and cues to view.

- A graph of current production jobs and statuses displays.

- The amount of production orders to release is shown as a cue.

- You can view and edit Production jobs without having to navigate into an MES or Time and Attendance screen.

- All the links for orders, journals, and Time and attendance forms are within a single click

- Even Resources are now linked to this workspace, so no need to navigate to an entirely different module!

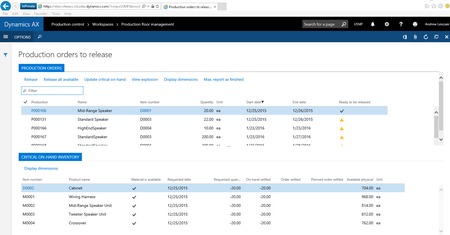

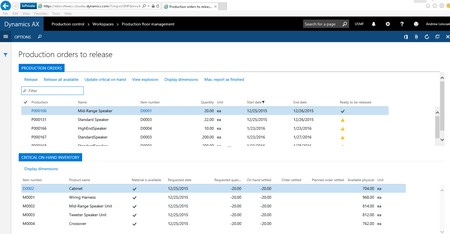

We’ll next view the Production orders to release page to show some enhancements that are long overdue for production planners and workers.

Right away what jumps out is the multi-pane structure of the form. This gives the ability to straight away see a Critical on-hand inventory check on items consumed in the Bill of Material for a given production order. Prior to new Microsoft Dynamics AX (V7), users would have to navigate through the BOM line by line to see on-hand inventory of each item within the BOM. Otherwise, users were often navigating back to the Released product to check the Max Report as Finished form. Now, the critical on-hand check is front and center, and the Max Report as Finished was added as a link directly in the form, giving one-click access, rather than two or three.

You can also update the critical on-hand display within the screen, as well, to get real time values in a fast-paced environment or if you are reviewing the form throughout the day.

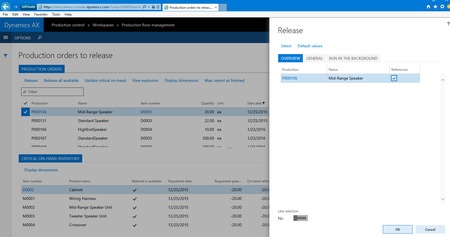

Using one of the same links in the form, it is now possible to quickly release all production orders that are available to be released at the same time by clicking the “Release all available” link:

Once clicked, a second screen opens with the orders that were available and clicking OK will update those productions orders to a status of “Released.” Once again, this a huge time-saving operation that would typically involve checking multiple orders in multiple screens to ensure inventory is available to begin production.

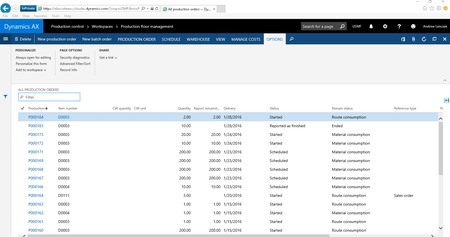

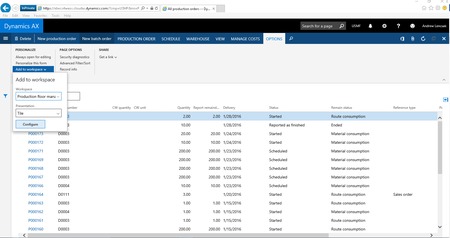

Now let’s check out the “All Production Orders” form. Not much has changed in terms of the information in the form itself, however, some really neat features have made it easier to get synced up with more information. For example, under Options you can quickly add the current form to your Workspace or Personalize it. Once again, easier and better than before.

You can actually add menus to any workspace you wish if there is one that you use more frequently. For example, I can add Productions orders to the Master Planning workspace and include the value count so it appears with the number of Production orders in it.

Similarly, if filters had been applied to that form, they could be saved as Favorites or added to workspaces just like how Cues worked in Microsoft Dynamics AX2012.

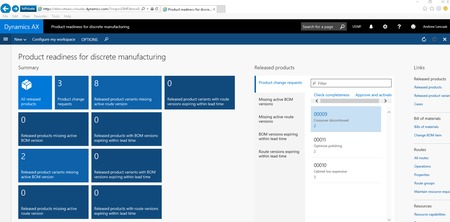

Another workspace that is extremely beneficial is the Product readiness workspaces. There is one for Discrete Manufacturing and one for Process Manufacturing. They both contain cues displaying related product setups that are incomplete or open engineering tasks, like Released products missing active BOM versions, and Product Change Requests.

This enables users with an easy view of open items to take care of before releasing products, BOMs, Formulas, and Routes to the production floor on production and batch orders. Change requests are done through the use of Case Management.

As you can see, through the use of well-defined Workspaces, an even easier Favorites function, and a smooth browser-based flow, the new Microsoft Dynamics AX (V7) has made it immeasurably easier to navigate, personalize, and manage a Production user’s experience. Good enough for a Production Planner, Production Line Manager, Production Supervisor, or Chief Operating Officer. With the capabilities upgrade from Microsoft Dynamics AX2009 to Microsoft Dynamics AX 2012 and R3, it is definitely a whole new world. Definitely worth considering upgrading to benefit from the new functionality that exists in manufacturing in Microsoft Dynamics AX 2012 R3 and the enhanced user experience that exists in the new Microsoft Dynamics AX (V7).

- About Us

- Partners

- Careers

- Contact us

- eBECS and the Microsoft Core Data Platform

- Microsoft Dynamics NAV in Property Management

- Microsoft Dynamics Nav Manufacturing Solutions

- Microsoft Dynamics NAV Cloud pricing

- Drive your Azure Momentum with SQL Managed Instance

- Compare Microsoft Dynamics AX VS NAV

- Microsoft Azure Data Centre Migration Guide

- Microsoft Dynamics 365 Business Central or 365 for Finance & Operations?

- Introduction to Microsoft Dynamics 365 for Finance and Operations

- Microsoft Dynamics 365 Business Central or 365 for Finance & Operations? Thank You

- Microsoft Dynamics 365 Business Central or Dynamics 365 Finance

- Compare Microsoft ERP Solutions

- Compare Microsoft ERP Solutions, Dynamics NAV vs Dynamics 365 Business Central

- Microsoft Dynamics 365 Business Central Price

- Compare Microsoft ERP

Categories

- AI (3)

- Azure (2)

- Business Insights (1)

- Canvas Apps (1)

- Common Data Service (2)

- Crisis Communication (1)

- CRM (3)

- Customer Data Platform (1)

- Customer Insights (1)

- Data Analytics/BI (29)

- Data Management (1)

- Data Warehouse (1)

- Dynamics 365 (33)

- Dynamics 365 Finance (1)

- Dynamics 365 Sales Insights (1)

- Dynamics 365 Supply Chain Management (1)

- Dynamics AX (50)

- Dynamics CRM (22)

- Dynamics Field Service (10)

- Dynamics NAV (10)

- Dynamics Project Service Automation (PSA) (15)

- eBECS (4)

- eBECS Marketing (1)

- eBECS Policies (1)

- ERP (2)

- Internet of Things (IoT) (15)

- Master Planning AX (4)

- Microsoft 365 (1)

- Microsoft Lifecycle Services (4)

- Power Apps (4)

- Power Automate (3)

- Power BI (1)

- Power Platform (6)

- Power VIrtual Agent (1)

- PowerApps (2)

- Project Service Automation (2)

- Quality Management (1)

- Sales (1)

- Surface Hub (3)

- Top Tips (1)

News

Upcoming Events - Register Now

Join our list

eBECS will invite you to webinars, events and keep you up to date with relevant news. You can unsubscribe at any time.