Standard Warehousing (WMS, or WMSII) versus Advanced Warehousing in Microsoft Dynamics AX (WAX, or WHS)?

You are here: >Standard Warehousing (WMS, or WMSII) versus Advanced Warehousing in Microsoft Dynamics AX (WAX, or WHS)?

In Microsoft Dynamics AX2012 R3, Microsoft introduced Advanced Warehousing, often called WAX, or WHS. This introduction became a “dynamic” shift for Microsoft ERP solutions bringing an industry standard advanced warehousing solution to the core of the product, eliminating the need for an expensive add-on or ISV module. This blog is intended to help users understand the major differences between the warehouse configurations, as well as how they are maintained. It can be used as a guide when trying to make a decision on which warehouse configuration you should utilize when implementing or upgrading to Microsoft Dynamics AX2012 R3.

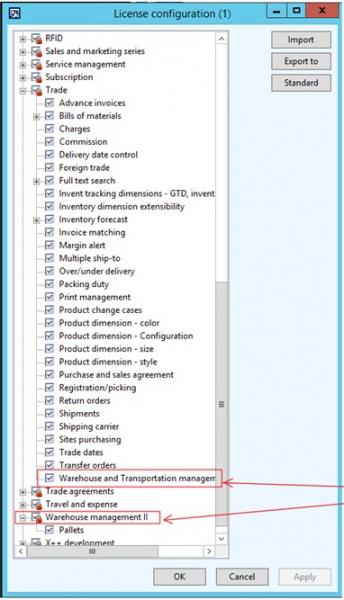

First, it is important to note that enabling both WMSII and WHS configuration keys is not recommended. Although, it is technically possible to enable both, Microsoft does not officially support the scenario of having both keys enabled due to data loss and creation concerns.

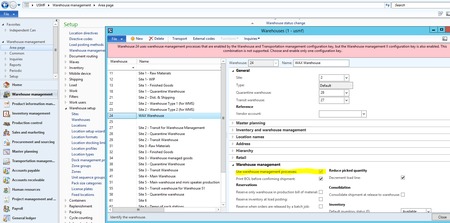

Management. We will focus on the features of Warehouse Management. In the setup section of the new Warehouse Management module is where your warehouse can now be created from. This form controls new features to enable a warehouse as WHS, or WAX controlled. Any warehouses without this selected, can continue to use standard AX features within the Stock Management module to support warehouse processes, other than deprecated features, which I will explain shortly.

You’ll notice the highlighted message at the top of the above screenshot. That is a warning if you enable both configuration keys to notify that it is not a supported option. Once the warehouse is setup by enabling the flag for the new warehouse management processes, we can begin to discuss the effects of that parameter. Below is a list of some features that are deprecated when turning off WMSII.

- WMS-forklifts

- Picking locations on warehouse items

- Location blocking causes

- Shipping templates

- Outbound rules

- Shipment reservation sequences and reservation combinations

- Store zones

- Store area’s

- Pallets and pallet types

- Pallet transport handling

- Standard consolidated shipping features

However, new functionality addressing those features, as well as much more, is now possible with WAX. Many of those features will be explored later in this blog.

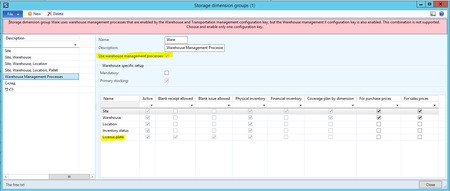

Next, we should take a look at the change in storage dimension groups settings. The storage dimension groups now also have a new flag to enable warehouse management processes:

What this does is allow you to setup certain items in storage dimension groups so you can separate items that need to use advanced warehousing with those that don’t. In combination with the warehouses, companies can now do mixed mode warehousing and meet whatever requirements they need by utilizing standard simple and advanced warehousing functionality within Microsoft Dynamics AX. If you operate in an organization that has many differing facilities where some are distribution centers, and some are just sales offices that hold little or no inventory, these controls will allow you to treat each warehouse to match the required business processes.

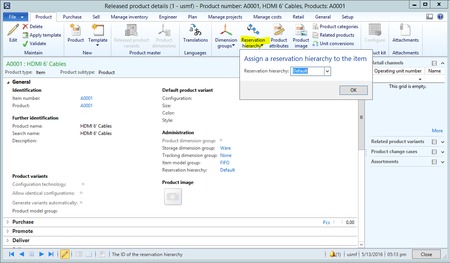

Another new important feature is the Reservation hierarchy. Items using advanced warehousing via the setting on the storage dimension group, will require a reservation hierarchy.

The reservation hierarchy setting controls the level at which a reservation is made. By that I mean, to what storage and tracking dimension levels are the reservations made at. For example, if the item is serial or batch controlled, those dimensions must be included in the reservation hierarchy:

Next, the sequence of the dimension determines where the reservation is actually placed. For example, in the above screenshot, serial number is last in the hierarchy and location is quite low as well. This is because most companies would only reserve an item at the site and warehouse level, regardless of the location the item is in or the serial number, which is essentially just used for tracking. So the reservation will ignore location and serial number and those two pieces of information would be recorded in the warehouse during the pick and ship process. However, if the company require reservations at the batch or serial number level, where specific batches or serial numbers were required and the warehouse should be told what to pick, the reservation hierarchy of the item should be set with those dimensions above the location.

Now, let’s get into the things that make a warehouse run in modern times. Advanced warehousing in Microsoft Dynamics AX2012 is intended to be used with Mobile devices. Most large warehouses, or any, that require the advanced functionality that will be described shortly, are utilizing handheld scanners, barcode readers, tablets, and phones. Typically, in an ERP system implementation, you must build custom workflows or large integrations between that transactions that are processed in the ERP database and the software available in the devices that are being used. The features in Microsoft Dynamics AX2012 R3 are linked to a Mobile device portal, so that any device that meets some minimum specifications, can process the AX work transactions the same way. You can find those specifications on Microsoft’s MSDN blog:

Once the portal is setup, you can also use that IP address to process Microsoft Dynamics AX work transactions through an internet browser if you are a smaller company who wants the advanced features, but do not have the volume or money to purchase new hardware (scanners, mobile phones, etc.).

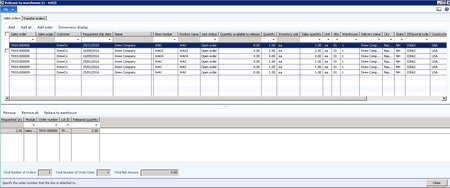

Finally, let’s take a high-level look at some of the major pieces of advanced functionality offered with WAX. It’s important to note that the setups described below control with a Release to Warehouse process to produce Warehouse Work. Warehouse work is effectively the transactions that can be processed in the various mobile device menus. For example, start and report as finished on a production order, warehouse picking and shipping of sales and transfer orders, purchase order receipt and putaway work, and so on. There are various options to control the Release of Warehouse work. It’s easiest to look at this concept from a sales order point of view for warehouse picking. Wave templates will be used to dictate which options are available based on your company’s business process. Also, whether you build a Load before sending work to the warehouse, let AX automatically create the loads, or manually consolidate loads during a later point in the warehouse process, will have a large effect on which option your company uses to Release to the Warehouse. For now, we’ll review 3 common examples: manual release directly from the sales order, manual release from the Release to Warehouse form, or automatic release through periodic batch jobs.

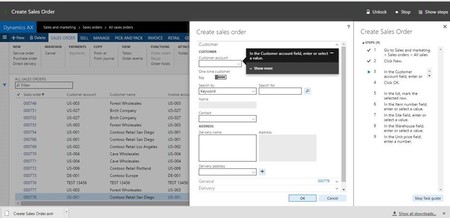

Manual Release to Warehouse from Sales Order

From the sales order, once inventory is reserved to the sales order, the button “Release to warehouse” can be selected from the Warehouse Management action ribbon tab

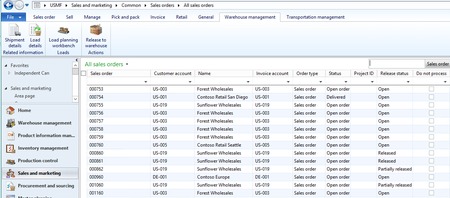

Manual Release from Release to Warehouse Form

There is a form in the Common section of the Warehouse Management module that can be used to review open sales and transfer order lines. With columns for showing what inventory is reserved to the sales order line, customer information, addresses and dates, this is a great form to control a manual review of what should be given to the warehouse based on priorities specific to your procedures. This is similar to the Release Sales order picking form that users are familiar with from previous versions of Microsoft Dynamics AX.

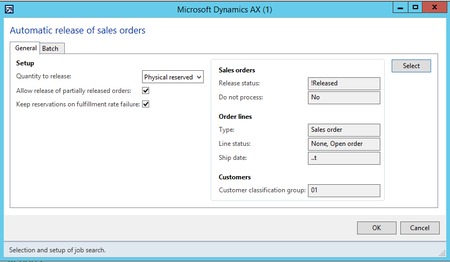

Automatic Release through Warehouse Management Periodic Batch jobs

The last option, and most useful if you have large volumes of transactions going through the warehouse, is to automate how work is released to the warehouse. There is a batch job for automatic release of sales orders work, and a corresponding job for transfer orders as well. This job allows you to specify selection criteria, so you dictate what gets released to the warehouse and when. For example, you may require a batch job to run in the morning for priority customers first, then at noon for standard, and another batch at the end of the day for intercompany transactions. Alternatively, you could have some items that get released automatically and others that must be released manually. This batch job can be run in coordination with or separately from the Process Waves batch job. The waves must be processed for work to be created.

As part of this section, below is a definition of some of the advanced setups required and utilized in Warehouse Management:

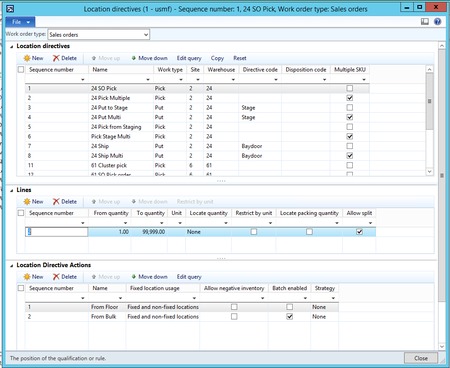

• Location directives: these control rules that help determine what pick and put locations are available for inventory movements and the sequence in which they should be considered. For example, in a sales order transaction, a location directive defines where the items will be picked from and where the picked items will be put. These rules are user-defined and can be based on many filters like alphanumeric by location, based on location profiles, or warehouse capacity. **Warehouse Capacity defined by location profile or Location stocking limits form.

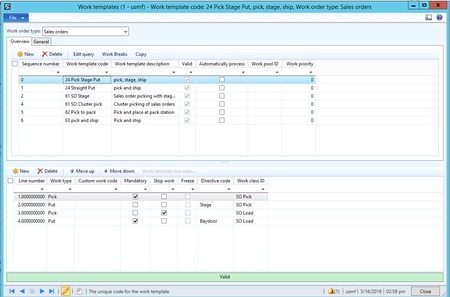

• Work templates: used to create and process warehouse work at various stages. Work templates are defined with at least one pick action and one put action, but can have more, as well as custom work actions. Work templates are available for the following:

Inbound transactions, like Receiving and putaway

Outbound transactions, sales picking and shipping

Production picking and Report as Finished

Transfer orders picking and shipping

Location to location transfers

Location replenishment (with no need for MRP)

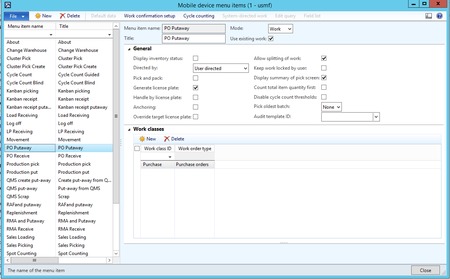

• Mobile menu items: define what work transactions and indirect activities, like inquiry screens, log off, etc. are available in the mobile device. They also control certain confirmations, rules, and other data that will display and be processed in the mobile device

• Replenishment: replenishment is a type of work that allows you to replenish locations with inventory based on sources of demand, without the need to link to MRP. There are two types of Replenishment strategies:

- Replenishment based on demand – This strategy creates replenishment work for outbound orders or loads if inventory is not available when the work is created by the wave. For example, if the quantity that is required for a sales order is not available when a wave is processed, replenishment work can be created.

- Replenishment based on minimum and maximum quantities – This strategy uses minimum and maximum stocking limits to determine when to replenish locations. The item and location criteria define the inventory that is evaluated for replenishment.

Replenishment templates are used to control these strategies for the timing and type of replenishment that occurs. Replenishment can then be triggered manually or in Periodic batch jobs.

With all of this functionality now built within the core of Microsoft Dynamics AX, any type or size of warehouse can be confident that their processes can be done efficiently. Please let eBECS know if there are any question related to configuring and designing your warehouse within Dynamics AX or if you have any other warehouse topics that you’d be interested in hearing about.

- About Us

- Partners

- Careers

- Contact us

- eBECS and the Microsoft Core Data Platform

- Microsoft Dynamics NAV in Property Management

- Microsoft Dynamics Nav Manufacturing Solutions

- Microsoft Dynamics NAV Cloud pricing

- Drive your Azure Momentum with SQL Managed Instance

- Compare Microsoft Dynamics AX VS NAV

- Microsoft Azure Data Centre Migration Guide

- Microsoft Dynamics 365 Business Central or 365 for Finance & Operations?

- Introduction to Microsoft Dynamics 365 for Finance and Operations

- Microsoft Dynamics 365 Business Central or 365 for Finance & Operations? Thank You

- Microsoft Dynamics 365 Business Central or Dynamics 365 Finance

- Compare Microsoft ERP Solutions

- Compare Microsoft ERP Solutions, Dynamics NAV vs Dynamics 365 Business Central

- Microsoft Dynamics 365 Business Central Price

- Compare Microsoft ERP

Categories

- AI (3)

- Azure (2)

- Business Insights (1)

- Canvas Apps (1)

- Common Data Service (2)

- Crisis Communication (1)

- CRM (3)

- Customer Data Platform (1)

- Customer Insights (1)

- Data Analytics/BI (29)

- Data Management (1)

- Data Warehouse (1)

- Dynamics 365 (33)

- Dynamics 365 Finance (1)

- Dynamics 365 Sales Insights (1)

- Dynamics 365 Supply Chain Management (1)

- Dynamics AX (50)

- Dynamics CRM (22)

- Dynamics Field Service (10)

- Dynamics NAV (10)

- Dynamics Project Service Automation (PSA) (15)

- eBECS (4)

- eBECS Marketing (1)

- eBECS Policies (1)

- ERP (2)

- Internet of Things (IoT) (15)

- Master Planning AX (4)

- Microsoft 365 (1)

- Microsoft Lifecycle Services (4)

- Power Apps (4)

- Power Automate (3)

- Power BI (1)

- Power Platform (6)

- Power VIrtual Agent (1)

- PowerApps (2)

- Project Service Automation (2)

- Quality Management (1)

- Sales (1)

- Surface Hub (3)

- Top Tips (1)

News

Upcoming Events - Register Now

Join our list

eBECS will invite you to webinars, events and keep you up to date with relevant news. You can unsubscribe at any time.